Understanding Packaging Design Cost: The True Investment Breakdown

Table of Contents

- Introduction: Cost vs. Value—A Necessary Mindset Shift

- The 5 Core Factors Driving Design Cost

- Cost Tiers: From Freelancer Rates to Full Agency Pricing

- The Impact of Structural Complexity on Budget

- Why SKU Count Multiplies the Final Price

- Hidden Costs: What Clients Often Forget to Budget For

- How Technical Requirements Influence the 3D Design Cost

- Strategies to Control and Optimize Your Packaging Budget

- Frequently Asked Questions (FAQs)

- The Packaging Cost Value Scorecard

- Conclusion: Making Your Budget Work Harder

Introduction: Cost vs. Value—A Necessary Mindset Shift

When a business asks about packaging design cost, they’re often seeking a simple, fixed number. However, the reality is that design is an investment, not just an expense. Just like building a house, the cost depends entirely on the blueprint, the materials used, and the level of expertise you hire. The initial outlay for professional packaging design services might seem high, but the resulting reduction in printing errors, increased shelf appeal, and stronger brand loyalty often yield a return on investment (ROI) that far outweighs the design cost.

The 5 Core Factors Driving Design Cost

Understanding the following variables is key to setting a realistic budget for any packaging project:

1. Scope of Work (The Complexity)

The difference between a basic product label and a custom, multi-component folding carton with inner trays is immense. Complexity directly translates to designer hours needed for concept, die-line creation, and material testing.

2. Service Provider Level

The experience and overhead of the designer or agency dictate the rate. A freelance designer typically offers the lowest rate, while a specialized packaging design agency (with strategic thinkers and engineers on staff) commands the highest fee. You are paying for their expertise and minimized risk.

3. Number of SKUs (Stock Keeping Units)

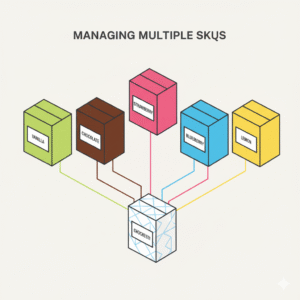

This is a critical multiplier. If you have a single design template but need to apply it to ten different flavors or sizes, the packaging design cost increases because each SKU requires unique technical file preparation, specific compliance checks (e.g., ingredients), and unique print-ready die-lines.

4. Customization and Special Finishes

Want gold foil, embossing, spot UV, or custom die-cut windows? These special finishes are beautiful but add significant design complexity. The designer must prepare highly technical artwork layers for the printer, requiring more time and meticulous attention to detail.

5. Research and Strategy

Does the project start with market research, consumer testing, and brand strategy development? If you hire an agency for a full brand audit before design begins, the cost will be higher, but the resulting design will be strategically superior and market-validated.

Cost Tiers: From Freelancer Rates to Full Agency Pricing

To give you an idea of typical packaging design cost (globally, with local rates often being competitive):

| Tier | Typical Provider | Service Focus | Estimated Price Range (USD Equivalent) |

| Basic | General Freelancer / Online Platforms | Simple label layouts, minimal revisions. | $500 – $1,500 per design |

| Intermediate | Experienced Freelancer / Small Studio | Custom graphic design, moderate structural guidance. | $1,500 – $4,000 per design |

| Premium | Specialized Agency | Structural engineering, brand strategy, testing, full production management. | $4,000 – $10,000+ per design |

The Impact of Structural Complexity on Budget

This is the hidden chakar in the cost structure. Structural design (the actual engineering of the container) is often more expensive than the graphic design.

- Standard Structure (Lower Cost): Using stock boxes (like standard mailers or off-the-shelf bottles) simplifies the process and keeps the design cost low.

- Custom Structure (Higher Cost): Designing a unique, proprietary box shape to make your product stand out requires dedicated structural engineering time, prototype testing, and the creation of new tooling for manufacturing—all of which significantly drive up the design budget.

Why SKU Count Multiplies the Final Price

Imagine you have a single product line, but it comes in 5 flavors. That’s 5 SKUs. Even if the graphic layout is 90% the same, a professional designer must produce 5 separate, flawless, and printer-ready die-lines and artwork files. This process ensures:

- Accurate Nutritional/Legal Text: No mix-ups between product variants.

- Color Consistency: Ensures different flavors maintain brand consistency.

- Error Prevention: Meticulous checking to avoid a costly print run mistake (like a wrong barcode or size).

Hidden Costs: What Clients Often Forget to Budget For

When budgeting for packaging design cost, clients must remember these common omissions:

- Mock-ups and Prototyping: Paying for physical samples of the final package (crucial for testing the structural design).

- Photography and Illustration: High-quality imagery or custom illustrations for the package artwork are separate costs.

- Brand Guideline Creation: If brand colors and typography are not defined, the designer must spend time establishing them.

- Licensing Fees: Paying for stock images, fonts, or unique design elements (like custom texture patterns).

How Technical Requirements Influence the Design Cost

A designer who provides only a JPG file is cheap. A professional who delivers print-ready vector files, accurately layered for finishes, color separation (CMYK), and die-line compliance is providing high value that protects your production budget. The cost of a professional reflects the time spent on technical perfection—the difference between a design that prints perfectly and one that forces you to scrap a whole manufacturing run.

Portfolio Showcase: Packaging Design Excellence

See how strategic design justifies the investment by checking out these samples: