Professional Packaging Design

Table of Contents

-

Industry Context: Why 2025 raised the stakes

-

Services & Features of professional packaging design

-

Scorecard: 12 evaluation points before you approve

-

Process (strategy → dieline → prepress → print)

-

Visual System & Information Hierarchy

-

Compliance & Risk Controls (non-legal)

-

Print Methods & Finishes

-

E-commerce Readiness (thumbnail → PDP → unboxing)

-

Sustainability (real impact, not greenwashing)

-

Common Mistakes & Quick Fixes

-

Files, Color & Prepress (what printers need)

-

Timelines, MOQs & Cost Levers

-

Hire CTA + Internal Portfolio Links

Industry Context: Why 2025 raised the stakes

-

Omnichannel parity: Packs must read at 120–160 px on marketplaces and still look premium in-store.

-

Multi-plant printing: Regional vendors are normal; color and dielines must be robust to avoid variant drift.

-

Spec transparency: Barcodes/QRs, batch/expiry windows, and UID fields are table stakes for traceability.

-

Sustainability pressure: Retailers reward mono-material structures, water-based coatings, and truthful end-of-life guidance.

-

Faster launches: Master systems and shared dies let you scale SKUs jaldi without rework.

Services & Features of Professional Packaging Design

-

Brand & pack architecture: SKU naming, variant logic, type scale, iconography, color families.

-

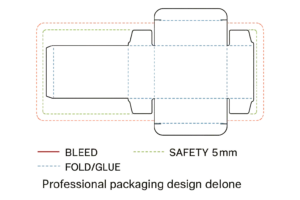

Structural CAD: cartons, sleeves, pouches, tubes, labels, SRP, shippers; bleed ≥ 3 mm, safety 3–5 mm.

-

Prepress governance: trapping 0.08–0.12 mm, overprint/knockout maps, rich black policy, total ink limits.

-

Color management: Pantone masters + LAB targets; ΔE ≤ 2.0; CMYK simulations; color bibles.

-

Security (as needed): microtext, UV inks, serialized QR with quiet zone ≥ 2.5 mm.

-

Pro photography & 3D: hero, macro finish, dieline blueprints, honest renders.

-

Sustainability roadmaps: right-weighting, mono-material swaps, disposal iconography & QR guidance.

-

Supplier enablement: RFQs, spec sheets, QC checklists, pallet patterns, change-control logs.

Scorecard: 12 Evaluation Points Before You Approve

-

Hierarchy that sells: brand → product → variant/strength → key RTB → net contents.

-

Thumbnail legibility: variant readable at 120–160 px on neutral background.

-

Bleed & safety: ≥ 3 mm bleed, 3–5 mm safety; small type off creases/vents.

-

Barcode/QR discipline: ANSI A/B grade; quiet zone ≥ 2.5 mm; off folds/varnish.

-

Trapping & overprint: 0.08–0.12 mm trapping; micro-type (≤8 pt) forced knockout.

-

Color control: Pantone + LAB; ΔE ≤ 2.0 vs master across plants.

-

Material fitness: board/film matches scuff, crush, MVTR/OTR needs.

-

Finish discipline: foil/spot gloss away from warnings/codes; coating weight specced.

-

SRP/peg readiness: tear paths tested; pegholes reinforced; front still merchandises post-open.

-

Sustainability honesty: recycled % and end-of-life icons with QR to regional guide.

-

Version control: rev codes on artboard, change log shared with vendors.

-

Dual-sourcing: at least two printers validated on the same spec.

Process (Strategy → Dieline → Prepress → Print)

-

Strategy & brief

Define audience, channels (grocery/pharmacy/DTC), regions, volumes, and competitors. Run shelf + thumbnail tests early to ground professional packaging design decisions. -

Content matrix

Lock copy order: claims, ingredients/actives, nutrition (if any), certifications, warnings, batch/expiry, variable data. Set max characters to avoid late reflows. -

Master visual system

12-column grid, type ramp (H1/H2/body/captions), icon family (dose, recycle, QR, CR), color logic per variant—never color-only. -

CAD & mechanics

Build dielines with 3 mm bleed / 5 mm safety; layers for fold/glue/varnish/foil/white ink/security; barcode/QR zones; SRP tear paths; peg holes. -

Prototypes & tests

White dummies + printed comps; fit on line, rub/scuff tests, drop/stack for SRP, peg trials, barcode scans, thumbnail legibility checks. -

Prepress

-

Images 300 ppi @100%; line art 1200 ppi.

-

Trapping 0.08–0.12 mm; rich black for large fills only (e.g., C60 M40 Y40 K100).

-

Overprint only where intended; verify in Overprint Preview.

-

Barcodes at spec magnification; quiet zone ≥ 2.5 mm; include sample scans.

-

-

Color sign-off

Wet proofs with LAB targets; reject above ΔE 2.0. Document CMYK sims when no spot ink. -

Press & QC

Capture ΔE, barcode grades, coating weights; photograph press OK samples; confirm SRP tear performance after packing speed tests. -

Handover kit

Final PDFs (PDF/X-1a or X-4), source files, color bible, preflight report, pallet patterns, revision log, reprint checklist.

Visual System & Information Hierarchy

-

Top band: brand + product family.

-

Primary signals: variant/strength badge, 1–3 word RTB, count/volume.

-

Secondary: certifications, sustainability icons, usage pictograms.

-

Tertiary: nutrition/actives tables, ingredients, legal line, batch/expiry windows.

-

Color & contrast: contrast ≥ 4.5:1 for small copy; pair hues with pattern or alphanumeric code.

-

Micro layout: codes 6–8 mm from edges/folds; align baselines across panels; avoid crowding near creases/vents.

Compliance & Risk Controls (non-legal)

-

Maintain a controlled master copy with version history; export per market if rules differ.

-

Don’t rely on color alone for strengths/variants—add symbols/patterns.

-

Reserve UID/serialization areas even if unused at launch.

-

Add tamper cues (arrows, “Lift to open”) when TE features exist.

-

Print disposal guidance appropriate to key regions; link a QR micro-site for updates.

(Guidance only—confirm with your regulatory team.)

Print Methods & Finishes

-

Litho offset for cartons/inserts—crisp micro-type and solids.

-

Flexo for labels/corrugate—manage plate counts and dot gain.

-

Digital (Indigo/inkjet) for pilots, low MOQs, variable data, market tests.

-

Finishes: aqueous matte/satin (retail-friendly), soft-touch sparingly (scuff visibility), spot gloss outside codes/warnings, cold foil/metallic inks for accents, emboss/deboss aligned to grain.

-

Security (when relevant): microtext, UV inks, guilloché, tamper labels—functional, not flashy.

E-commerce Readiness (thumbnail → PDP → unboxing)

-

Thumbnail: variant readable at 120–160 px; neutral background; avoid micro-claims.

-

PDP gallery (6–8 images): hero, side info table, macro finish, barcode/QR with highlighted quiet zone, inside-lid/leaflet view, size in hand, SRP/pallet shot.

-

Downloads: AI/PDF dielines, prepress checklist, color bible, disposal guide PDF.

-

Unboxing: step-by-step TE removal or assembly; QR video for quick start.

-

Color honesty: renders must match print within ΔE tolerance—no oversaturation.

Sustainability (real impact, not greenwashing)

-

Right-weighting: reduce caliper where compression allows; publish gram savings.

-

Mono-material structures: paper tray or molded fiber instead of mixed laminations where feasible.

-

Coatings: water-based over plastic laminations unless barrier is essential.

-

Design for disassembly: avoid glued mixed materials; clear disposal icons + QR for regional rules.

-

Claim discipline: printed recycled % and certifications only—seedha, truthful.

Common Mistakes & Quick Fixes

-

Artwork misfit on machinery → Add chamfers; verify tuck/flap lengths; confirm glue areas.

-

Barcode fails at DC → Move off seam; increase contrast; quiet zone ≥ 2.5 mm; re-grade to A/B.

-

Overprint on fine text → Force knockout for ≤8 pt; audit Overprint Preview.

-

Color drift across plants → One color bible; press OK per facility; ΔE ≤ 2.0.

-

SRP tears ugly → Tune perf ratio; add start notch; test at packing speed.

-

Scuffy soft-touch → Switch to satin/eggshell or raise coating weight; add slip sheets.

Files, Color & Prepress (what printers need)

-

Finals: PDF/X-1a or X-4; fonts outlined; profiles embedded; sources archived.

-

Layers (named, non-printing): dieline, fold, glue, varnish, foil, emboss, white ink, security, barcode/QR zones, overprint/knockout legend.

-

Bleed ≥ 3 mm; safety 3–5 mm; keep micro-type off creases/vents.

-

Images 300 ppi @100%; line art 1200 ppi; total ink limit per press profile.

-

Pantone governance: book + LAB; ΔE ≤ 2.0; rich black recipe for solids (not micro-type).

-

Barcodes/QR: magnification, height, placement; quiet zone ≥ 2.5 mm; attach sample scan report.

-

Preflight report: color spaces, overprints, fonts, resolution, trim/bleed boxes.

Timelines, MOQs & Cost Levers

-

Strategy + system: 1–2 weeks

-

CAD + comps: 5–7 days

-

Prepress + proofs: 3–5 days

-

Printing: digital 3–5 days; offset/flexo 10–14 days incl. drying & QC

-

MOQs: digital 100–500; offset 5k–20k; flexo labels 5k+

-

Levers: shared dies, standardized calipers, fewer spot colors, gang runs, localize artwork—not structure; dual-source printers.

Hire Us + Internal Portfolio Links

Need professional packaging design that prints clean and sells fast? We build master systems, enforce color, and enable multi-plant printing—friendly process, factory-ready files.

-

Supplements & label systems (regulated hierarchy discipline):

https://usmandesigner.com/portfolio/supplement-label-design-freelancer/ -

High-fidelity consumer packs & 3D visuals:

https://usmandesigner.com/portfolio/vape-packaging-design-store/ -

Premium cartons & complex dielines:

https://usmandesigner.com/portfolio/sushi-packaging-design/FAQs

1) What makes packaging truly “professional”?

A system that covers strategy, CAD accuracy, prepress control, color governance (LAB/ΔE), and supplier enablement—so files print right the first time.2) Do I need Pantone inks?

Anchor key colors with Pantone + LAB; simulate in CMYK if proofs meet ΔE ≤ 2.0 to master.3) How big should my bleed and safety be?

Use ≥ 3 mm bleed and 3–5 mm safety; keep small text and codes away from creases/vents.4) Why do barcodes fail at retailers or DCs?

Missing quiet zones, low contrast, wrong magnification, or codes placed on folds. Grade to ANSI A/B before approval.5) What is trapping—and why care?

A micro overlap (0.08–0.12 mm) where inks meet, preventing hairline gaps after register shift.6) How can I make packs greener without huge cost?

Right-weight board, switch to water-based coatings, prefer mono-material inserts, and print clear disposal guidance via QR.7) When to choose digital vs offset/flexo?

Digital for pilots/variable data/low MOQs; offset for premium cartons; flexo for labels/corrugate at volume.