Packaging Design and Supply

Table of Contents

-

Industry Context: Why 2025 changed the game

-

Services & Capabilities across packaging design and supply

-

Scorecard: 12 evaluation points before you approve

-

Process: Strategy → CAD dieline → Prepress → Procurement → Print

-

Visual System & Information Hierarchy

-

Compliance & Risk Controls (non-legal, high-level)

-

Print Methods, Materials & Finishes

-

E-commerce Readiness (thumb → PDP → unboxing)

-

Sustainability that’s real (not greenwashing)

-

Common Mistakes & Quick Fixes

-

Files, Color & Prepress (what printers need)

-

Timelines, MOQs & Cost Levers

-

Hire CTA + Internal Portfolio Links

Industry Context: Why 2025 changed the game

-

Compressed launches: DTC and marketplace listings demand photo-ready packs and instant repeat runs.

-

Input volatility: Board, film, and ink costs swing; dual-sourcing and standard specs reduce exposure.

-

Data-first operations: COA scans, barcode grading, and color ΔE reports are normal QC artifacts, not nice-to-haves.

-

Sustainability pressure: Regulators and retailers prefer mono-material choices, recycled content, and recyclability claims with proof.

-

Global logistics: Lead times depend on port congestion and holidays—your spec must allow regional equivalents without brand drift.

Services & Capabilities across Packaging Design and Supply

-

Brand & pack architecture: SKU hierarchy, naming, color system, size logic.

-

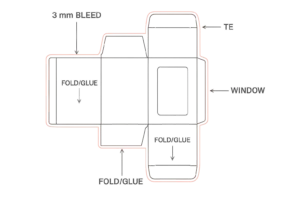

CAD dielines: cartons, sleeves, labels, pouches, tubes, bottles, inserts, shippers.

-

Material engineering: SBS/FBB, corrugate grades (E/B flute), films (BOPP/PET/PE), closures (CR), barrier needs (MVTR/OTR).

-

Prepress governance: bleeds (≥3 mm), trapping (0.08–0.12 mm), overprint/knockout maps, Pantone LAB targets.

-

Vendor sourcing: RFPs, sampling, press trials, supplier scorecards, service-level terms.

-

Quality operations: barcode grading A/B, ΔE ≤ 2.0, security labels, serialization windows.

-

Logistics: pallet patterns, carton ECT/BCT checks, cube optimization, export docs.

-

Sustainability road-mapping: mono-material redesigns, caliper right-weighting, coatings, take-back/QR leaflets.

Scorecard: 12 evaluation points before you approve

-

Front-panel hierarchy: brand → product → variant/strength → net contents.

-

Barcode & QR: quiet zone ≥ 2.5 mm; 99% scan pass; QR leads to verified page.

-

Color control: Pantone masters with ΔE ≤ 2.0; proofs signed with readouts.

-

Die accuracy: fold/glue tolerances fit filling equipment; no choke points.

-

Bleed & safety: bleed ≥ 3 mm; safety 3–5 mm; small type knocks out (no overprint).

-

Material spec: board/film meets compression, scuff, and barrier needs.

-

Tamper/CR: clear instructions with icons; perforation or induction seal verified.

-

E-comm legibility: strength/variant readable at 120–160 px thumbnails.

-

Compliance copy: all mandatory fields present (batch/expiry, warnings).

-

Sustainability: mono-material where possible; end-of-life icons honest.

-

Palletization: master carton pass drop/stack tests; efficient cube.

-

Supplier readiness: at least two approved vendors with matched specs.

- 3D Renderings for your Product

Process: Strategy → CAD Dieline → Prepress → Procurement → Print

-

Strategy & brief

-

Audience, channels (retail vs DTC), volumes, regions.

-

Competitive shelf and thumb tests.

-

-

Content matrix

-

Lock exact text order: claims, legal, ingredients, compliance icons.

-

Pre-count character limits to prevent last-minute reflows.

-

-

Visual system

-

12-column grid, type scale (headline/body/captions), icon family, color logic by variant.

-

-

CAD & mechanics

-

Build dielines with 3 mm bleed, 5 mm safety, glue areas, TE features, hang holes, window options.

-

Validate on machinery (cartoner, labeler, shrink).

-

-

Prototype & testing

-

White dummy + printed comps; drop tests; scuff tests with common shipper rubs.

-

-

Prepress

-

Raster at 300 ppi @100%, line art 1200 ppi.

-

Trapping 0.08–0.12 mm where inks meet; small text = knockout.

-

Overprint only for rich blacks/registration marks; never on tiny type.

-

Barcodes at spec magnification; quiet zones reserved.

-

-

Procurement & vendor set-up

-

Issue RFQs with print run splits; require press OK and ΔE report.

-

Lock ALT materials (e.g., FBB↔SBS) with tolerance table.

-

-

Press & QC

-

Approve wet proofs; collect ΔE, barcode grade, coating weight.

-

In-line serialization/UID windows tested in RIP.

-

-

Inbound & fulfillment

-

Master carton labels with SKU, LOT/EXP, QR to spec sheet; pallet patterns optimized.

-

-

Reorder & change control

-

Versioning: update logs, archive master PDFs, notify all vendors of new rev.

Visual System & Information Hierarchy

-

Top zone: brand mark and product class.

-

Primary signals: variant/strength badge, count/volume, RTBs (key benefits).

-

Secondary: usage icons, certifications, disposal guidance.

-

Tertiary: ingredients table, nutrition/actives, legal line, batch/expiry windows.

-

Color & contrast: avoid color-only differentiation; pair with pattern or icon; contrast ≥ 4.5:1 for body text.

-

Micro-layout: barcodes away from folds/edges; keep 6–8 mm from carton edge.

Compliance & Risk Controls (non-legal, high-level)

-

Maintain a master controlled copy and version history.

-

Don’t overclaim sustainability; tie claims to standards or recycled content % that you can prove.

-

Reserve UID/serialization space even if not used at launch.

-

Child-resistance and tamper instructions must be icon-led and near the opening zone.

-

Keep QR links live for at least 24 months post-batch date.

(Guidance only—confirm with your regulatory counsel.)

Print Methods, Materials & Finishes

-

Litho offset: folding cartons, inserts; crisp text and color fidelity.

-

Flexo: labels, corrugate; efficient at volume.

-

Digital (HP Indigo/inkjet): low MOQs, variable data, pilots.

-

Materials:

-

SBS/FBB 300–400 gsm for premium cartons.

-

Corrugate E/B flute for shippers; ECT 32+ as needed.

-

Films: BOPP, PET, PE; laminate for barrier where required.

-

-

Finishes: aqueous (matte/satin), soft-touch sparingly, spot gloss on non-critical areas, cold foil for accents, emboss/deboss aligned with board grain.

-

Security: UV inks, microtext on seams, tamper tapes.

E-commerce Readiness (thumb → PDP → unboxing)

-

Thumbnail: variant/strength readable at 120 px; simple background; no tiny claims.

-

PDP gallery (6–8 images): hero, side with info table, macro of finish, scale in hand, backside with barcode/QR, sustainability panel, pack-in-box shot.

-

Unboxing: one insert or inside-lid print for quick-start; QR to usage/how-to; avoid loose leaflets if QR suffices.

-

Color honesty: match ΔE to physical pack; avoid oversaturation that misleads.

Sustainability that’s real (not greenwashing)

-

Right-weighting: optimize caliper; remove unnecessary inserts.

-

Mono-material: paper tray instead of plastic where protection allows.

-

Coatings: water-based over plastic laminations unless barrier needed.

-

Design for disassembly: avoid glued mixed materials; clear consumer instructions.

-

Claims discipline: print recycling logos applicable to your markets only; link QR to disposal guide by region.

Common Mistakes & Quick Fixes

-

Artwork doesn’t fit machinery → Re-check tuck flaps, glue tabs; add chamfers on tight folds.

-

Barcode fails at DCs → Increase contrast, move off seam, enforce quiet zone, re-grade to A/B.

-

Overprint on fine text → Force knockout ≤8 pt; audit overprint preview.

-

Color drift across vendors → Single color bible; press OK at each plant; ΔE ≤ 2.0.

-

Crushed corners on shippers → Upgrade to B flute or raise ECT; improve pallet wrap pattern.

-

Late material swaps → Pre-approve ALT spec with tolerance ranges and visual sign-off.

Files, Color & Prepress (what printers need)

-

PDF/X-1a or X-4 finals, fonts outlined; include a live, editable source in archive.

-

Layers: dieline, fold, glue, varnish, foil, emboss, white ink, security—separate and named.

-

Bleed ≥ 3 mm; safety 3–5 mm; no critical text near creases.

-

Images 300 ppi; line art 1200 ppi; total ink limit per press profile.

-

Pantone with LAB values; rich black (e.g., C60 M40 Y40 K100) only for large areas, not small type.

-

Barcode spec (UPC/EAN): height, magnification, location; quiet zone fixed.

-

Preflight report: color spaces, overprint flags, font embedding, image resolution, trim box.

Timelines, MOQs & Cost Levers

-

Strategy + system: 1–2 weeks.

-

CAD + comps: 5–7 days.

-

Prepress + proofs: 3–5 days.

-

Printing: digital 3–5 days; offset 10–14 days incl. drying.

-

MOQs: digital 100–500; offset 5k–20k; flexo labels 5k+.

-

Levers: unify board calipers, standardize colors, gang runs, simplify tooling (shared dies), carton footprints aligned to pallet patterns, localize art not structure.

Hire Us + Internal Portfolio Links

Want packaging design and supply without firefighting? We build a production-ready system, vet vendors, and deliver QC that scales. Chalo, ship with confidence.

-

Supplements & label systems:

https://usmandesigner.com/portfolio/supplement-label-design-freelancer/ -

High-fidelity consumer packs & renders:

https://usmandesigner.com/portfolio/vape-packaging-design-store/ -

Complex carton craftsmanship & dielines:

https://usmandesigner.com/portfolio/sushi-packaging-design/FAQs

1) What’s the minimum info a retail pack must show?

Brand, product, variant, net contents, legal/mandatory fields, barcode, and a batch/expiry or lot area if relevant to your category.2) How do I keep color consistent across vendors?

Use Pantone masters with LAB references, sign wet proofs, enforce ΔE ≤ 2.0, and keep a color bible shared in every PO.3) When should I choose digital vs offset?

Digital for pilots/low MOQs/variable data; offset for steady SKUs at volume with stricter unit cost.4) What’s the simplest way to improve barcode passes?

Increase contrast, protect quiet zones (≥2.5 mm), avoid varnish underneath, and grade to A/B before print approval.5) Can I make my pack more eco-friendly without retooling?

Yes: reduce caliper, switch to water-based coatings, standardize mono-material trays, and print disposal guidance with a QR to regional instructions.6) How do I avoid crushed corners in transit?

Use correct flute/ECT, test pallet wrap patterns, add corner protectors, and optimize master carton orientation.7) What’s the fastest route from concept to shelf?

Lock the content matrix early, build a reusable master dieline, pre-approve two vendors, and run a short digital pilot before offset scale-up.