Graphic Design Packaging: Typography, Color & Conversion (Not Just “Pretty”)

Graphic design packaging is where your visuals do the heavy lifting—turning brand strategy into a 5-second read that wins on shelf and at 120×120 px online. This 2025-ready guide covers hierarchy, typography, color systems, imagery, iconography, compliance, print production, and e-commerce assets—so your packaging looks premium and performs.

Table of Contents

-

What Is “Graphic Design Packaging” (and what it isn’t)

-

Strategy → Visuals: Claim Architecture & the 5-Second Read

-

Typography That Sells (and Survives Print)

-

Color Systems & Variant Logic

-

Imagery, Illustration & Iconography

-

Information Architecture & Compliance (Readable and Legal)

-

Prepress: From Dieline to Press-Ready PDF

-

Print Methods & Finishes (Without Wasting Budget)

-

E-commerce Readiness (Thumbnail → Unboxing)

-

Sustainability Signals Without Green-washing

-

Workflow You Can Actually Ship

-

Common Mistakes & Fast Fixes

-

Image Prompts (Hero, Grid, Macro, Dieline, Before/After)

-

FAQs

-

Rank Math Data (Copy-Paste)

1) What Is “Graphic Design Packaging” (and what it isn’t)

It’s not decoration. It’s the visual system that makes structure usable and messaging unmistakable:

-

Clear hierarchy (brand → variant → benefit → 2–3 proof icons → net wt.).

-

Tight type pairing and color logic that scale to new SKUs.

-

Production-ready files that print cleanly and read at a glance.

See strong hierarchy and variant color logic you can adapt:

Sushi Packaging Design →

Vape Packaging Design Store →

Dog Supplement Label Design →

2) Strategy → Visuals: Claim Architecture & the 5-Second Read

Start with three building blocks:

-

Primary promise (1 line): “Air-Fried • 40% Less Oil” / “Zero Sugar • 180mg Natural Caffeine.”

-

Proof set (2–3 icons): halal/vegan/non-GMO/recyclable.

-

Variant logic: flavor or effect is the largest text after the brand.

Front panel reading order:

-

Brand mark

-

Product/Variant (largest)

-

Primary promise

-

Proof icons (2–3 only)

-

Net weight

3) Typography That Sells (and Survives Print)

-

Pair one display + one workhorse text family. Avoid three+ fonts on front.

-

Weights & sizes: push variant to the max; keep minimum sizes ≥6–7pt real-world.

-

Contrast & keylines: plan for condensation/low light; add subtle keylines around light text on gradients/photos.

-

Kerning/Tracking: tighten display headlines; loosen small legal text slightly for legibility.

-

OpenType discipline: set numeral styles, fractions (nutrition), small caps if used.

4) Color Systems & Variant Logic

-

Assign functional colors per flavor/benefit: Chili=red, Lime=green, Calm=lavender, Zero=silver.

-

Lock values (HEX/CMYK/Spot) in your style guide; limit plates to control cost.

-

Ensure light/dark pairs for accessibility. Test at 120×120 px and 1–2 m shelf distance.

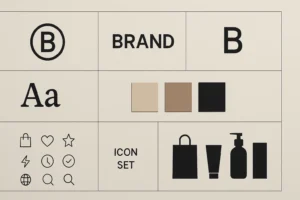

5) Imagery, Illustration & Iconography

-

Imagery: appetite macros for food; clean photoreal 3D for supplements/cosmetics.

-

Illustration: bold, simple shapes outperform fussy detail on busy shelves.

-

Icons: 6–12 total in a reusable set (nutrition, certifications, disposal). Keep stroke & corner radius consistent; define min size.

Playful, high-contrast confectionery tone for inspiration:

KickBallz Candy Packaging →

6) Information Architecture & Compliance (Readable and Legal)

-

Front: brand → variant → benefit → 2–3 icons → net wt.

-

Back/side: story, ingredients, nutrition/INCI, allergens (bold “Contains”), usage/storage, barcode, batch/lot, certs, translations.

-

Localization: dedicate a panel or QR for overflow; don’t micro-type the front.

-

Keep a locked Compliance Layer aligned to the dieline.

7) Prepress: From Dieline to Press-Ready PDF

-

Color: CMYK + named spot colors; consistent profiles.

-

Images: linked, embedded on export; effective resolution ~300 ppi at print size.

-

Overprint/Knockout: avoid overprint on light text; set rich blacks appropriately (and 100% K for barcodes).

-

Bleed/Safe: 3 mm (⅛”) bleed typical; keep text inside safe.

-

Barcodes: quiet zone intact; test at 100% print scale.

-

Proofs: request soft and hard proofs; annotate deltas on the actual stock.

8) Print Methods & Finishes (Without Wasting Budget)

-

Digital: pilots/short runs, seasonal.

-

Flexo: CPG scale.

-

Gravure: huge runs, tight color.

-

Label vs. sleeve vs. direct print: choose based on SKU count & curves.

Finishes: matte (modern), soft-touch (tactile), spot UV/foil (sparingly on logo/claims), emboss/deboss for premium. Plan scuff resistance for logistics.

9) E-commerce Readiness (Thumbnail → Unboxing)

-

Front = poster. Design at 120×120 px first, then scale up.

-

PDP gallery: front hero, angled back (compliance), lifestyle, in-hand scale, short unboxing GIF.

-

Copy near first image: three proof bullets in plain language.

-

3D render pipeline: consistent angles/lighting across SKUs; swap to photos later if needed.

10) Sustainability Signals Without Green-washing

-

Right-size the pack; reduce void and plates.

-

Prefer mono-materials; add honest disposal icons (“recycle where facilities exist”).

-

Test finishes on actual stock; some laminations/foils affect recyclability.

-

Avoid vague “eco” claims—be specific and verifiable.

11) Workflow You Can Actually Ship

-

Brief & moodboard (category codes, tone, claims).

-

Dieline lock with printer stock & barrier notes.

-

Concepts (2–3) stress-tested at shelf + thumbnail sizes.

-

Refinement + compliance (nutrition/INCI, allergens, certs, barcodes, translations).

-

Prepress (profiles, trapping, overprint, barcode scale).

-

Press/first article (adjust to real stock/ink).

-

Asset kit (print-ready PDFs, layered source, 3D renders, PDP set).

12) Common Mistakes & Fast Fixes

-

Everything screams on front. → Enforce hierarchy; move story to side/back.

-

Variant chaos. → Fix color bands + icon set + naming rules.

-

Barcode fails. → 100% K on white; correct quiet zone; test at print scale.

-

Grease bleed on kraft. → Specify grease-resistant liner or change stock.

-

Thumbnail mush. → Larger variant, fewer words, higher contrast.

14) FAQs

Q1. What’s the difference between packaging design and graphic design packaging?

Packaging design covers structure + materials + compliance; graphic design packaging focuses on the visual system (type, color, imagery, icons) that sits on that structure.Q2. How many fonts should I use on a pack?

Usually two: one display, one text family. Add italics/weights instead of new fonts.Q3. Should I design in RGB or CMYK?

Design for print in CMYK/spot from the start; keep a separate RGB export profile for web images.Q4. Minimum text size for print?

Avoid going below 6–7 pt for body/ingredients; test on the actual stock and finish.Q5. Can I put certifications on the front?

Only if earned and meaningful to buyers; misuse damages trust.Q6. What files will my printer want?

Press-ready PDFs on final dielines (1:1), outlined fonts, embedded images, CMYK/spot profiles, barcode sized correctly, plus a locked Compliance Layer.

Hire a Designer Who Turns Art into Conversion

Need graphic systems that look premium and perform—on shelf and online? Explore relevant tones: