Cigarette Box Design Template

Table of Contents

-

Industry Context: Why 2025 is different

-

Services & Features for a robust template

-

Scorecard: 12 evaluation points before approval

-

Process (strategy → dieline → prepress → print)

-

Visual System & Hierarchy inside a constrained canvas

-

Compliance & Risk Controls (high-level, non-legal)

-

Print Methods, Materials & Finishes

-

E-commerce Readiness (thumbnail → PDP → unboxing)

-

Sustainability without greenwashing

-

Common Mistakes & Quick Fixes

-

Files, Color & Prepress: what printers need

-

Timelines, MOQs & Cost Levers

-

Hire CTA + Internal Portfolio Links

Industry Context: Why 2025 is different

-

Tighter regulation windows: Health warnings, plain packaging rules, and placement logic vary by market and change frequently. Templates must be modular with locked zones for warnings and tax stamps.

-

Counterfeiting pressure: Serialized QR/UIDs are increasingly common; your template must reserve distinct quiet zones and tamper paths.

-

Omnichannel selling: Even when retail is primary, listings and approvals now require photo-accurate proofs and 3D previews.

-

Sustainability scrutiny: Less lamination, recyclable boards, and credible disposal guidance—no vague “eco” claims.

-

Rapid varianting: Flavors/strengths/size packs require color governance and pattern systems that stay consistent at ΔE ≤ 2.0.

Services & Features for a Robust Template

-

Master CAD dieline for soft-pack and hinged-lid (flip-top) cartons; optional hard-pack variants.

-

Regulated copy architecture: health warning frames, pictorials, tax stamps, track-and-trace fields, manufacturer/address lines.

-

Color governance: Pantone masters + LAB targets; overprint/knockout rules; trapping 0.08–0.12 mm at ink joins.

-

Anti-counterfeit layer: microtext, UV marks, guilloché, serial QR + human-readable UID, tear tape controls.

-

E-comm readiness: thumbnail legibility at 120–160 px; hero angle consistency; on-white compliant images.

-

Sustainability options: FSC FBB/SBS, water-based coatings, mono-material thinking where feasible.

Scorecard: 12 Evaluation Points Before Approval

-

Warning zone compliance (size %, placement, rotation where required).

-

Tax stamp & track-and-trace windows reserved with quiet zones ≥ 2.5 mm.

-

Color control: Pantone + LAB; press proof ΔE ≤ 2.0 to master.

-

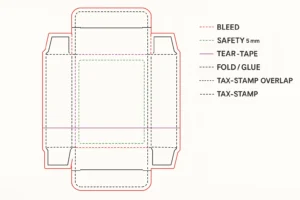

Bleeds & safety: bleed ≥ 3 mm, safety 3–5 mm around all critical text.

-

Barcode/QR: location off folds; scannability (ANSI grade A/B).

-

Trapping/overprint: 0.08–0.12 mm; no overprint on small text (≤8 pt) or thin rules.

-

Tamper cues: tear tape direction, “lift/peel” arrows where applicable.

-

Hierarchy: brand marks secondary to legal warnings (where mandated) yet consistent across panels.

-

Material spec: board caliper, stiffness, scuff resistance; foil or metallized film constraints declared.

-

E-comm thumbnails: variant/family legible at 120–160 px.

-

Security features: microtext legibility and UV hit positions pass line trials.

-

Version control: template revision noted on artboard + change log.

Process (Strategy → Dieline → Prepress → Print)

-

Strategy & market matrix

-

Map markets (A/B/C) with warning %, pictorial rotation needs, tax stamp positions, and serialization formats.

-

-

Content architecture

-

Lock all mandatory copy: health warnings, tar/nicotine statements (if required), manufacturer lines, barcodes/UIDs, website/quitline where mandated.

-

-

Master visual system

-

Define category colors/patterns; ensure not dependent on color alone for SKU differentiation.

-

-

Dieline development

-

Hinged-lid & soft-pack: establish flaps, hinge panel, top/bottom panels; add 3 mm bleed, 5 mm safety; show wrap direction; reserve tax stamp and tear tape paths.

-

-

Prototypes (white & printed comps)

-

Check warning frame cuts, hinge alignment, stamp overlap, and tear tape behavior.

-

-

Prepress

-

Convert spot colors; build overprint/knockout map; set trapping 0.08–0.12 mm; images at 300 ppi @100%; line art 1200 ppi.

-

Barcodes at spec magnification with quiet zone ≥ 2.5 mm; test scan.

-

-

Security embedding

-

Place microtext (≥0.3 mm cap height), UV hits, guilloché; reserve serialized QR zone and test with actual code lengths.

-

-

Press proof & sign-off

-

Hard proof with ΔE readouts; no approval if over tolerance; sign rich black usage policy (solids only, not small type).

-

-

Line trial

-

Verify folding, tear tape, tax stamp application, and scuff resistance.

-

-

Handover kit

-

Locked PDF/X, source files, color bible, barcode/QR specs, revision log, and photo guidelines for e-comm.

Visual System & Hierarchy Inside a Constrained Canvas

-

Top/Front panel: warning frame dominates where required; brand zone below/aside per regulation.

-

Side panels: ingredients/constituent table (if required), manufacturer address, barcodes/UID, recycling/disposal icons.

-

Back panel: second warning, quitline/website, tax stamp overlap area.

-

Color logic: consistent hue per variant; pair with pattern or alphanumeric code; maintain contrast ≥ 4.5:1 for small text.

-

Iconography: disposal, no-sale age mark, QR/UID symbol, microtext key.

-

Do not crowd folds: keep 6–8 mm clear from folds for small text and codes.

Compliance & Risk Controls (High-Level, Non-Legal)

-

Maintain controlled master copy; record rev codes on artboard and file name.

-

Separate market law layers (A/B/C) for easy toggling; export market-specific masters.

-

Don’t rely on color alone to differentiate variants; add pattern, numeral, or symbol.

-

Keep UID/serialization and tax stamp areas flexible; never place under varnish/foil that reduces readability.

-

Integrate tamper directions if tear tape/induction seals are used.

Note: Guidance only. Always validate with legal/regulatory experts for each jurisdiction.

Print Methods, Materials & Finishes

-

Litho offset on FBB/SBS 260–320 gsm for hinged-lid; soft-pack often uses printed OPP + inner foil wrap (where legal).

-

Finishes: aqueous matte/satin for cleanability; soft-touch sparingly (shows scuffs); spot gloss away from warnings/codes; cold foil only in non-regulated zones.

-

Security: UV invisible inks, microtext, emboss/deboss on tax stamp area if allowed; tamper tear tape alignment marks.

-

Scuff & rub: request scuff tests vs common shipper board surfaces; mandate coating weight ranges.

E-commerce Readiness (Thumbnail → PDP → Unboxing)

-

Thumbnail (120–160 px): variant code + family name readable; warning area visible as required—no misleading crops.

-

PDP gallery (6–8 images): front, side (barcode/UID), top with tax-stamp window, macro of microtext/UV mark, hinge close-up, in-hand scale, flattened dieline.

-

Downloads: market-specific cigarette box design template PDFs/AI with bleed/safety, overprint/knockout legend, barcode/QR placement guide.

-

Unboxing: show tear-tape path and stamp interaction; ensure photos reflect real ΔE to print.

Sustainability Without Greenwashing

-

Prefer FSC-certified boards; right-weight caliper where compression allows.

-

Use water-based coatings over plastic laminations unless barrier is required.

-

Design for mono-material where feasible; avoid mixed lamination combinations that hinder recycling.

-

Provide clear disposal icons applicable to the market; link QR to region-wise guidance.

-

Report real recycled content %; avoid vague claims.

Common Mistakes & Quick Fixes

-

Warning misplacement → Lock a grid with pinned warning frames; use market layer toggles.

-

Barcode on folds → Relocate to flat panel; maintain quiet zone ≥ 2.5 mm; re-grade scan to A/B.

-

Overprint on small type → Force knockout for ≤8 pt text; check in Overprint Preview.

-

Color drift → Use Pantone + LAB; demand press ΔE report; sign one color bible across vendors.

-

Tax stamp clash → Reserve overlap window in dieline; share a stamp jig diagram.

-

Tear tape tearing art → Add unprinted “tape lane” and arrow cues; test with real adhesive.

Files, Color & Prepress: What Printers Need

-

Finals: PDF/X-1a or X-4; fonts outlined; source files archived.

-

Layers (non-printing): dieline, fold, glue, varnish, foil, emboss, white ink, security, warning masks, market A/B/C.

-

Bleed ≥ 3 mm; safety 3–5 mm; avoid minuscule rules near creases.

-

Images 300 ppi; line art 1200 ppi; total ink limit per press profile.

-

Pantone governance: master chips + LAB values; ΔE ≤ 2.0 to approve.

-

Barcodes/QR: magnification & height spec; quiet zone ≥ 2.5 mm; location callouts.

-

Serialization: variable fields tested in RIP; human-readable fallback.

-

Overprint/knockout legend printed on pasteboard with swatches.

Timelines, MOQs & Cost Levers

-

Strategy + market matrix: 3–5 days (faster if matrix pre-exists).

-

CAD + template build: 4–6 days (two pack types).

-

Prepress + security: 3–5 days (proof + UV plate test).

-

Press: digital pilots 3–5 days; offset runs 10–14 days incl. drying & QC.

-

MOQs: digital 100–500 sets (for pilots); offset commonly 5k–20k per SKU.

-

Levers: unify board calipers; limit spot colors; gang-run variants; standardize tax-stamp window and tear-tape geometry across SKUs.

Hire Us + Internal Portfolio Links

Need a compliant, scalable cigarette box design template that prints clean and passes audits? We’ll build your master, lock color/security, and set you up for fast variant launches—bina tension.

-

Label & supplement systems (strict hierarchy discipline):

https://usmandesigner.com/portfolio/supplement-label-design-freelancer/ -

High-fidelity consumer packs & 3D renders:

https://usmandesigner.com/portfolio/vape-packaging-design-store/ -

Complex carton craft & dielines:

https://usmandesigner.com/portfolio/sushi-packaging-design/FAQs

1) What must be included in a cigarette box design template?

Locked warning frames, tax-stamp/serialization windows, barcode/QR placement, dieline with ≥3 mm bleed and 5 mm safety, overprint/knockout legend, and color governance.2) How do I keep color consistent across plants?

Use Pantone with LAB values, sign wet proofs, enforce ΔE ≤ 2.0, and maintain one color bible across vendors.3) Where should the barcode and QR go?

A flat side/back panel away from folds with quiet zone ≥ 2.5 mm; avoid varnish/foil underneath; grade scans to A/B.4) Can I use foil and emboss with heavy warnings?

Yes, but keep enhancements outside regulated zones; confirm stamp/tear-tape paths; avoid reflective finishes under codes.5) How do I handle multiple markets with different warning rules?

Use market layers (A/B/C) in the template; export per-market masters; keep a versioned matrix of warning sizes/positions.6) What security elements are realistic at scale?

Microtext, UV inks, guilloché lines, unique QR/UID, and controlled tear-tape. Holographics only where budget allows and regulations permit.7) What’s the fastest path from concept to press?

Start with a compliant master dieline, finalize the content matrix, run a digital pilot, then scale to offset with press OK and ΔE reports.