Industrial Packaging Design: Prioritizing Protection, Logistics, and Strength

Table of Contents

- Introduction: Design for Survival, Not Shelf Appeal

- Industrial vs. Consumer: A Fundamental Difference in Purpose

- The 5 Non-Negotiable Attributes of Structural Integrity

- Key Material Choices for Heavy-Duty Industrial Packaging

- Design Challenges: Addressing Logistics and the Supply Chain

- The Role of Custom Inserts and Cushioning

- Cost-Efficiency: Right-Sizing and Maximizing Stacking Strength

- Compliance and Safety: Legal Requirements for Bulk Shipping

- Frequently Asked Questions (FAQs)

- The Industrial Packaging Scorecard

- Conclusion: The Unseen Pillar of Manufacturing

Introduction: Design for Survival, Not Shelf Appeal

In the world of industrial packaging design with 3D Products, the primary audience isn’t the final consumer; it’s the supply chain—the forklifts, the warehouse managers, and the long-haul trucks. Unlike consumer packaging, which prioritizes color and emotional appeal, industrial packaging focuses on durability, strength, and logistical efficiency.

Industrial packaging’s only job is to safeguard heavy machinery parts, bulk chemicals, sensitive electronics, or automotive components through challenging transportation and storage conditions. This is a field where structural engineering is paramount, and failure is measured in damaged inventory and millions in loss.

Industrial vs. Consumer: A Fundamental Difference in Purpose

Understanding this distinction is key to successful industrial design:

| Aspect | Industrial Packaging | Consumer Packaging |

| Primary Purpose | Protection, Storage, and Transportation of goods in bulk. | Attraction, Branding, and enhancing the unboxing experience. |

| Key Focus | Structural Integrity, stackability, cost-efficiency. | Visual aesthetics, messaging, and ease of use. |

| Materials | Heavy-duty corrugated cardboard, wooden crates, metal drums, specialized foam. | Lightweight paperboard, plastics, glass, high-quality printing. |

| Audience | Businesses (B2B), warehouse workers, logistics partners. | End-users (B2C), shoppers. |

The 5 Non-Negotiable Attributes of Structural Integrity

For a piece of industrial packaging to be considered successful, it must pass these structural tests:

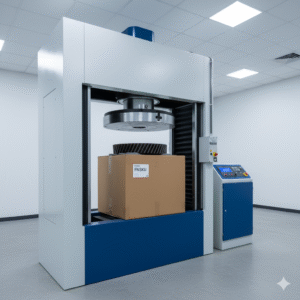

- Compression Strength: The packaging must be rigid enough to resist crushing when stacked high in a warehouse (this is often measured by the Edge Crush Test or ECT rating).

- Impact Resistance: It must absorb shocks and vibrations during rough handling and transportation (the classic drop test).

- Weight Tolerance: It must be designed to safely support the full weight of the product and often the weight of other stacked packages.

- Ergonomics: The design must be easy for warehouse staff to handle, lift, and open (e.g., proper hand-holes, logical palletization).

- Environmental Protection: It must seal and protect the contents from dust, moisture, and contamination throughout the logistics pipeline.

Key Material Choices for Heavy-Duty Industrial Packaging

The choice of material directly impacts the required structural design. The most common materials include:

- Corrugated Fiberboard: The foundation of industrial packaging. Used for heavy-duty cartons, trays, and inserts. Its strength is measured by its flute size and board thickness.

- Wood Crates and Pallets: Essential for extremely heavy or bulky items (like machinery or large components) that require maximum support and rigidity.

- Protective Foam/Inserts: Materials like polyurethane or Expanded Polystyrene (EPS) foam are used inside the outer container to cushion fragile items and hold them rigidly in place, preventing movement and shock damage.

- Metals: Used for drums and barrels when transporting liquids, chemicals, or materials requiring high chemical compatibility and temperature resistance.

Design Challenges: Addressing Logistics and the Supply Chain

The biggest challenge in industrial packaging design is balancing protection with logistics costs:

- Transportation Costs: Poorly optimized packaging (too bulky or too heavy) drastically increases shipping costs. Smart design requires right-sizing to maximize cargo capacity on trucks and pallets.

- Stacking Strength vs. Damage: Ensuring the packages stack safely without collapsing (a huge chakar in warehousing) requires technical calculations, not guesswork.

- Scalability: The design must be easy to implement and scale up for mass manufacturing environments without slowing down the production line.

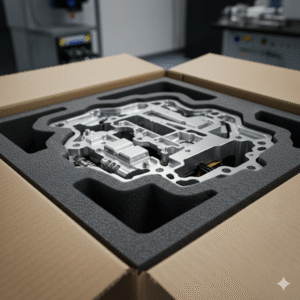

The Role of Custom Inserts and Cushioning

For many industrial products, the outer box is only part of the solution. Custom inserts (often made using CNC machinery, like your specialization, Usman bhai!) are critical for:

- Rigidity and Bracing: Holding heavy, irregularly shaped parts (like automotive components) rigidly in place so they don’t shift during transit.

- Vibration Dampening: Providing a custom-fit cushion to absorb external shocks for sensitive electronics or scientific equipment.

- Organization: Separating delicate parts within a single box to prevent them from damaging each other.

Compliance and Safety: Legal Requirements for Bulk Shipping

Industrial packaging has strict regulatory requirements focused on safety, especially for chemicals or hazardous goods. Designs must include:

- Hazardous Material Labeling: Clearly communicating risks and handling instructions.

- Shipping Marks: Large, clear markings for handling (e.g., arrows indicating “This Way Up”) and tracking codes.

- Regulatory Compliance: Adherence to international standards for safe bulk shipment and transport (like UN certification for certain materials).

Portfolio Showcase: Packaging Design Excellence

See how our strategic approach to structural design solves complex industrial challenges and guarantees product safety: