Disposable Food Packaging Suppliers

Table of Contents

-

Industry Context: Why 2025 is different

-

Services & Features you should expect

-

Scorecard: 12 evaluation points before you approve

-

Process (strategy → CAD → prepress → print)

-

Visual System & Information Hierarchy

-

Compliance & Risk Controls (high-level, non-legal)

-

Print Methods, Materials & Finishes

-

E-commerce Readiness (thumbnail → PDP → unboxing)

-

Sustainability (real impact, not greenwashing)

-

Common Mistakes & Quick Fixes

-

Files, Color & Prepress (what printers need)

-

Timelines, MOQs & Cost Levers

-

Hire CTA + Internal Portfolio Links

Industry Context: Why 2025 is different

-

Delivery & marketplace photos dominate. Packaging must survive steam, stacking, and transport while still looking crisp in 120–160 px thumbnails.

-

Material scrutiny. Buyers ask about PFAS, recyclability, compostability, and credible certifications. Suppliers who can document coatings and substrates win bids.

-

Color truth across reorders. Multi-plant printing means Pantone + LAB targets and ΔE ≤ 2.0 tolerance are now table stakes.

-

SKU sprawl & speed. Limited specials, collabs, and seasonal menus need modular dielines and fast variable printing.

-

Traceability. Batch/expiry fields, barcodes/QR, and tamper labels are increasingly required even for QSR/fast-casual brands.

Services & Features you should expect

-

Menu-fit engineering: bowls with snap lids, vented clamshells, trays with compartments, pizza boxes with cross-vents, hot/cold cups, paper bags, cup carriers, tamper bridges.

-

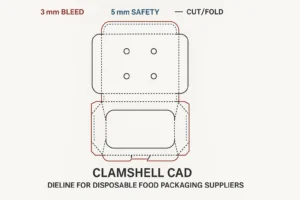

Master CAD dielines: bleed ≥ 3 mm, safety 3–5 mm, fold/glue/vent markers, carry handles, sauce wells; SRP shipper options.

-

Food-contact guidance: coating and ink advisories per contact/non-contact zones; grease, heat, and condensation management.

-

Prepress & color governance: trapping 0.08–0.12 mm, overprint/knockout maps, rich black policy, Pantone + LAB with ΔE ≤ 2.0.

-

Data & coding: barcode/QR placement with quiet zone ≥ 2.5 mm, batch/expiry windows, allergen labels.

-

Photography & 3D: on-white heroes, macro finish shots, dieline blueprints, and in-use imagery for marketplaces.

-

Supply planning: lead-time calendars, surge plans, dual-plant options, and pallet patterns for DCs.

Scorecard: 12 evaluation points before you approve

-

Leak & steam control: lid geometry, venting pattern, and coating weight tested with your actual dishes.

-

Stackability: lids stay latched after a delivery ride; ECT/BCT verified for shippers.

-

Food-safe inks/coatings: documented for contact areas; grease resistance proven.

-

Tamper evidence: seals or bridge labels with intuitive “Peel here” arrows.

-

Barcode/QR performance: ANSI A/B grade, quiet zone ≥ 2.5 mm, off folds and high-gloss.

-

Bleed & safety: ≥ 3 mm bleed, 3–5 mm safety; no critical text near creases/vents.

-

Trapping & overprint discipline: 0.08–0.12 mm trapping; small text (≤8 pt) forced knockout.

-

Color control: Pantone + LAB; ΔE ≤ 2.0 vs master proof.

-

Thermal/micro tests: safe under heat lamps or microwave (as applicable).

-

Sustainability claims: verifiable (recycled %, certifications); mono-material options prioritized.

-

Lead times & surge capacity: realistic calendars, holiday buffers, backup materials.

-

Cost transparency: caliper, coating, plate counts, finish costs, and freight logic itemized.

Process (strategy → CAD → prepress → print)

-

Strategy & menu mapping

Portion sizes, wet/dry items, sauce behavior, travel distance, and photo needs. Decide core forms (bowl, clamshell, tray, pizza) and accessory SKUs. -

Content matrix

Allergen icons, reheating/storage notes, disposal guidance, batch/expiry fields, QR links for menu or nutrition. -

Master visual system

12-column grid, type ramp, icon family (halal/vegan/spicy/recycle/QR), variant/brand color logic. -

CAD & mechanics

Build dielines with 3 mm bleed / 5 mm safety. Add vent holes, lid snaps, tape lanes, handle tests, and barcode/QR zones. -

Prototypes & stress tests

Fill with hot/cold items; run shake, stack, and condensation tests; do courier ride; grade barcode scans. -

Prepress

-

Images 300 ppi @100%; line art 1200 ppi.

-

Trapping 0.08–0.12 mm; small text = knockout; rich black only for large fills (e.g., C60 M40 Y40 K100).

-

Overprint only where intended; verify in Overprint Preview.

-

Barcode magnification per symbology; quiet zone ≥ 2.5 mm; include sample scans.

-

-

Color sign-off

Wet proofs with LAB targets; reject above ΔE 2.0; document CMYK simulations if no spot inks. -

Press & QC

Record ΔE, barcode grades, coating weights; photograph press OK; confirm vent cuts and lid fits post-packing. -

Handover kit

Final PDFs (PDF/X-1a or X-4), source files, color bible, preflight report, pallet patterns, and revision log.

Visual System & Information Hierarchy

-

Front panel / lid top: brand + dish name or category; one short RTB (e.g., “Hot & Sealed”).

-

Sides: allergen icons, reheating pictos, disposal guidance, QR to menu or reheat video.

-

Base/side panel: barcode with clear quiet zone, batch/expiry and plant code windows.

-

Color & contrast: maintain ≥ 4.5:1 contrast for small copy; never rely on color alone—pair with icons/letters.

-

Micro layout: keep codes 6–8 mm from folds and vents; avoid varnish over codes.

Compliance & Risk Controls (high-level, non-legal)

-

Keep a controlled master copy with versioning; only one source of truth.

-

Distinguish SKUs by more than color; add symbols/patterns.

-

Reserve serialization/batch space even if not used at launch.

-

Use food-contact suitable inks/coatings where contact occurs; document MSDS/CoC via suppliers.

-

Tamper instructions must sit near the seal path; don’t cover with varnish or foil.

Note: Guidance only. Validate with your regulatory and QA teams.

Print Methods, Materials & Finishes

-

Litho offset for graphic cartons/clamshells (tight micro-type).

-

Flexo for corrugate pizza boxes and kraft bags (manage plate count/dot gain).

-

Digital (Indigo/inkjet) for promos/low MOQs/variable data.

-

Materials

-

SBS/FBB 300–400 gsm clamshells/trays with grease-resistant, food-safe coatings.

-

Corrugate E/B flute pizza and meal kits (request ECT 32+ as needed).

-

Paper bowls + lids; evaluate fit and steam venting; check microfiber shedding.

-

Paper bags & carriers with reinforced handles.

-

-

Finishes: aqueous matte/satin (food-safe), soft-touch sparingly (shows scuffs), spot gloss away from safety text/codes.

-

Security: tamper labels, perforations; optional microtext/UV in brand zones—never over barcodes.

E-commerce Readiness (thumbnail → PDP → unboxing)

-

Thumbnail (120–160 px): clear brand and dish/category; avoid crowded claims.

-

PDP gallery (6–8 images): hero with food, macro of vent/lock, leak test, dieline blueprint with bleed/safety, QR placement, stack test, bag + carrier shot.

-

Unboxing: step-by-step seal removal; reheating pictograms; QR to short video.

-

Color honesty: renders should match print within ΔE tolerance—no oversaturated fakes.

Sustainability (real impact, not greenwashing)

-

Right-weighting: tune caliper for compression; publish gram savings per 1k units.

-

Mono-material first: paper + water-based coatings where barrier allows; avoid mixed laminations that block recycling.

-

Compostable/recyclable clarity: don’t over-claim; print icons and plain-language guidance relevant to your markets; link a QR page with region-wise instructions.

-

Design for disassembly: no unnecessary plastics; minimize glued mixed materials; clear labels for lids vs bases.

-

Evidence: recycled content %, certifications, and coating specs documented and shareable during audits.

Common Mistakes & Quick Fixes

-

Soggy or leaking boxes → Add vent pattern; upgrade coating weight; redesign lid snap geometry.

-

Barcode fails at DC → Move off seam; increase contrast; protect quiet zone ≥ 2.5 mm; re-grade to A/B.

-

Overprint on fine text → Force knockout for ≤8 pt; audit Overprint Preview.

-

Color drift across plants → One color bible; press OK per plant; enforce ΔE ≤ 2.0.

-

Seal confusion → Add “Peel here” arrows and micro-copy; keep adhesive path unprinted.

-

Soft-touch scuffs → Switch to satin/eggshell or raise coating weight; add slip sheets.

Files, Color & Prepress (what printers need)

-

Finals: PDF/X-1a or X-4, fonts outlined; profiles embedded; sources archived.

-

Layers (named, non-printing): dieline, fold, glue, varnish, foil (if any), white ink, security, barcode/QR zones, overprint/knockout legend, vent markers.

-

Bleed ≥ 3 mm; safety 3–5 mm; keep micro-type away from creases/vents.

-

Images 300 ppi @100%; line art 1200 ppi; total ink limit per press profile.

-

Pantone governance: book + LAB values; ΔE reporting; rich black recipe for fills (not micro-type).

-

Barcodes/QR: magnification, height, placement; quiet zone ≥ 2.5 mm; sample scan report attached.

-

Preflight report: color spaces, overprints, fonts, resolution, trim/bleed boxes.

Timelines, MOQs & Cost Levers

-

Strategy + menu mapping: 3–5 days

-

CAD + comps: 5–7 days

-

Prepress + proofs: 3–5 days

-

Printing: digital 3–5 days; offset/flexo 10–14 days incl. drying & QC

-

MOQs: digital 250–1,000; offset/flexo 5k–50k depending on format

-

Levers: shared dies, standardized calipers, fewer spot colors, gang runs, standard seal label sizes, localize artwork—not structure; dual-source vendors.

Hire Us + Internal Portfolio Links

Shortlist disposable food packaging suppliers who bring engineering + color discipline—not just cartons. We’ll design modular dielines, enforce prepress rules, and set up dual-plant supply—jaldi, quality intact.

-

Supplements & label systems (regulated hierarchy discipline):

https://usmandesigner.com/portfolio/supplement-label-design-freelancer/ -

High-fidelity consumer packs & 3D visuals:

https://usmandesigner.com/portfolio/vape-packaging-design-store/ -

Premium cartons & complex dielines:

https://usmandesigner.com/portfolio/sushi-packaging-design/FAQs

1) What products do disposable food packaging suppliers usually provide?

Clamshells, bowls/lids, trays, pizza boxes, paper bags, cup carriers, labels, and tamper seals tailored to your menu and delivery profile.2) How do I prevent leaks and sogginess?

Use the right coating weights and lid geometry, add vent holes for steam, and prototype with real dishes before mass print.3) What should my print files include for suppliers?

≥ 3 mm bleed, 3–5 mm safety, trapping 0.08–0.12 mm, overprint/knockout legend, Pantone/LAB targets, and barcode/QR with quiet zone ≥ 2.5 mm.4) Are water-based coatings enough for greasy items?

Often yes at the right weight; for extreme grease, specify liners or specialty barriers—always test with your actual foods.5) How do I keep color consistent across plants?

Maintain one color bible, sign wet proofs, and enforce ΔE ≤ 2.0 with LAB targets for every vendor.6) Can I claim compostable or recyclable on pack?

Only if verifiable. Print precise claims and provide disposal guidance via QR by region; avoid vague “eco friendly” language.7) What’s a sensible MOQ to start?

Digital pilots from 250–1,000; scale to offset/flexo at 5k–50k once specs and demand are stable.