Web Design Packaging

Table of Contents

-

Industry Context: Why 2025 is different

-

Core Services & Features for Web Design Packaging

-

Scorecard: 12 evaluation points

-

Process (strategy → UX → CMS → prepress assets → launch)

-

Visual System & Information Hierarchy

-

Compliance & Risk Controls (non-legal)

-

Print Methods & Finishes (how to present them on the site)

-

E-commerce Readiness (thumbnail → PDP → unboxing content)

-

Sustainability (communicating without greenwashing)

-

Common Mistakes & Quick Fixes

-

Files, Color & Prepress (what printers need—and how to host it online)

-

Timelines, MOQs & Cost Levers

-

Hire CTA + Internal Portfolio Links

Industry Context: Why 2025 is different

-

B2B behaves like D2C. Distributors and brand managers expect instant pricing, 3D configurators, and live lead times.

-

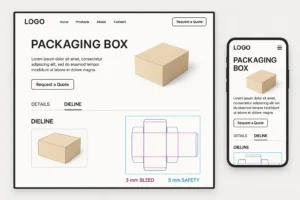

Spec clarity wins. Sites that show dielines (with ≥3 mm bleed), trapping guides (0.08–0.12 mm), and overprint/knockout rules reduce back-and-forth and close faster.

-

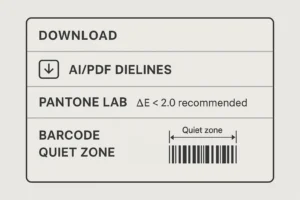

Color confidence online. You must document Pantone governance with LAB values, ΔE tolerances, and side-by-side CMYK simulations.

-

Camera shopping. PDP images must read at 120–160 px; barcodes/QRs need visible quiet zones in photos and downloads.

-

Sustainability scrutiny. Buyers want proof: material specs, recycled content %, and end-of-life guidance—no vague claims.

Core Services & Features for Web Design Packaging

-

Site architecture for packaging (Materials → Formats → Sizes → Finishes → MOQ/lead time).

-

Product templates for cartons, labels, pouches, tubes, corrugate—each with spec tabs and CAD downloads.

-

Spec library: dielines (AI, PDF), prepress checklist, Pantone/ΔE guide, barcode placement rules.

-

Price/RFQ systems: tiered MOQ logic, freight estimator, custom quote workflow.

-

3D mockups & AR: browser-based model viewer, true-to-scale packs.

-

Configurator: size sliders, board caliper, finish toggles, security options (TE labels, holograms).

-

Sustainability dashboard: materials matrix, recyclability icons, certificates.

-

Content stack: case studies, blog, comparison charts, downloadable checklists.

Scorecard: 12 evaluation points

-

Navigation clarity: users find their pack type in ≤2 clicks.

-

PDP readability at thumbnail: variant name + key spec legible at 120–160 px.

-

Spec completeness: dieline with 3 mm bleed, 5 mm safety, fold/glue, TE callouts.

-

Prepress rules: trapping (0.08–0.12 mm), overprint/knockout map, rich black guidance.

-

Color governance: Pantone master, LAB targets, ΔE ≤ 2.0 published.

-

Barcode/QR: quiet zones ≥ 2.5 mm stated; demo images show correct placement.

-

Configurator logic: outputs valid SKUs, MOQs, and lead times without dead ends.

-

Conversion plumbing: RFQ form with file upload, sample request, and WhatsApp click-to-chat.

-

Performance: LCP < 2.5s; image CDNs; lazy-loaded 3D.

-

Trust signals: COA/QA process page, plant photos, press-OK checklist.

-

Sustainability proof: recycled % and disposal guidance by region; no vague “eco” badges.

-

Schema & SEO: Article/FAQ/Product schema; Rank Math fields complete.

Process (strategy → UX → CMS → prepress assets → launch)

-

Discovery & segmentation

-

Target users (brand owners, print buyers, ops). Map their primary jobs (quote fast, verify spec, order samples).

-

-

UX blueprint

-

Card-sort navigation; 12-column grid; sticky spec tabs (Materials, Dieline, Finishes, Compliance).

-

-

Content matrix

-

Lock mandatory spec copy per product: board caliper, flute, finish, MOQ, tolerance, barcode rules, overprint/knockout notes.

-

-

Component design

-

PDP sections: hero gallery, price/RFQ, configurator, spec downloads, FAQ, reviews, sustainability.

-

-

Prepress asset creation

-

Dielines with ≥3 mm bleed, 5 mm safety, fold/glue/TE layers (non-printing).

-

Trapping guide (0.08–0.12 mm), Pantone LAB & ΔE notes, barcode quiet zone diagrams.

-

-

CMS & data

-

Variant tables, finish libraries, color bibles, MOQ ladders, shipping rules.

-

-

3D & imagery

-

Neutral lighting, honest color (ΔE notes), macro shots for finishes; e-comm thumbnails tested at 120 px.

-

-

QA & accessibility

-

Contrast ≥ 4.5:1; keyboard nav; alt texts include the exact product and web design packaging where relevant.

-

-

Launch & analytics

-

Goal tracking for RFQs, sample requests, configurator completes; heatmaps on PDP spec tabs.

-

-

Scale

-

Add calculators (pallet/cube, caliper vs crush), market landing pages, and a prepress “Upload & Preflight” tool.

Visual System & Information Hierarchy

-

Top band: product name + variant; primary CTA (“Get Instant Quote”).

-

Spec ribbon: MOQ, lead time, material, finish icons.

-

Image rail: hero → macro finish → dieline blueprint → in-hand scale → palletization.

-

Tabs: Dieline & Prepress, Print Methods & Finishes, Sustainability, Compliance, Downloads.

-

Color coding: one hue per category (Cartons/Labels/Pouches), with neutral backgrounds to keep color accuracy believable.

-

Iconography: TE, CR, recycle, barcode, QR, Pantone chip, ΔE badge.

Compliance & Risk Controls (non-legal)

-

Publish a master controlled copy for each product spec PDF; version every change (rev codes).

-

Provide UID/serialization fields on labels/cartons; recommend placement and font specs.

-

Warn against relying on color alone for variant differentiation; suggest patterns/symbols.

-

Add a tamper instruction panel template for TE labels/shrink.

Note: Guidance only—confirm with your regulatory team.

Print Methods & Finishes (how to present them on the site)

-

Litho offset (cartons/inserts): crisp text; show photos of micro-type.

-

Flexo (labels/corrugate): plate count vs unit cost chart.

-

Digital (Indigo/inkjet): low MOQs, variable data; note limits for metallics/spot whites.

-

Finishes: aqueous (matte/satin), soft-touch (smudge caution), spot gloss (avoid over warnings), foil/emboss (show register tolerances).

-

Security: microtext, UV inks, holographic threads—display macro photos and where to place them.

E-commerce Readiness (thumbnail → PDP → unboxing content)

-

Thumbnail: strength/variant readable at 120–160 px; no busy backgrounds.

-

PDP: 6–8 images—hero, dieline blueprint with bleed/safety, macro of finish, barcode placement with quiet zone box, sustainability icons, pallet shot.

-

Unboxing content: step-by-step TE removal image; QR video for assembly (tuck flaps, crash lock).

-

Downloads: AI/PDF dielines, prepress checklist, color bible, barcode size spec.

Sustainability (communicating without greenwashing)

-

Publish material matrices with recycled % and regional recyclability.

-

Suggest mono-material options; mark exceptions where barrier is required.

-

Show right-weighting case studies (board caliper reduction vs compression).

-

Provide disposal guidance by region via QR; keep claims specific and provable.

Common Mistakes & Quick Fixes

-

Glamour images only → Add dieline and prepress tabs; conversions will rise.

-

No barcode rules → Provide quiet zone diagram and approved placements; reduce print fails.

-

Over-saturated renders → Note color honesty; include ΔE and Pantone references.

-

Hidden RFQ → Keep “Get Instant Quote” sticky; add sample request CTA.

-

Slow galleries → Use WebP/AVIF; lazy-load; CDN.

-

One vendor lock-in → Explain dual-sourcing with equivalent specs to build buyer trust.

Files, Color & Prepress (what printers need—and how to host it online)

-

Downloads per product:

-

Dieline AI/PDF with ≥3 mm bleed, 5 mm safety, non-printing layers for dieline/fold/glue/varnish/foil/white ink/security.

-

Trapping rules (0.08–0.12 mm), overprint/knockout map, rich black policy (e.g., C60 M40 Y40 K100 for large solids only).

-

Pantone & LAB targets; ΔE ≤ 2.0 tolerance note; CMYK simulations.

-

Barcode spec (UPC/EAN magnification, height) with quiet zone ≥ 2.5 mm.

-

Preflight checklist (PDF/X, image resolution 300 ppi, line art 1200 ppi, total ink limit).

-

Timelines, MOQs & Cost Levers

-

Discovery/UX: 1–2 weeks

-

Design system & components: 1 week

-

Content & prepress assets: 3–7 days

-

Build & integrations: 1–2 weeks

-

QA & launch: 3–5 days

-

Levers: reusable PDP templates, shared dieline library, standardized finish icons, calculator components, modular pricing tables.

-

MOQs: publish tiers clearly; let users toggle digital vs offset to see cost/lead impact.

Hire Us + Internal Portfolio Links

Need a site that sells packaging—not just shows it? We design the UX, build the CMS, and ship a full web design packaging stack with specs, calculators, and 3D that buyers trust.

-

Supplements & label systems (spec-heavy layouts):

https://usmandesigner.com/portfolio/supplement-label-design-freelancer/ -

High-fidelity consumer packs & 3D visuals:

https://usmandesigner.com/portfolio/vape-packaging-design-store/ -

Premium cartons & complex dielines:

https://usmandesigner.com/portfolio/sushi-packaging-design/FAQs

1) What pages are must-have for web design packaging?

Home, Category (by format/material), PDP with spec tabs, RFQ/instant quote, Spec Library, Sustainability, QA/Press-OK, Case Studies, and a Prepress Upload page.2) How do I handle complex variant logic?

Use a configurator tied to a SKU rules engine (size ranges, caliper, finishes). Output a valid quote with MOQ/lead time and downloadable dieline.3) How do I present color accurately online?

Publish Pantone LAB targets, show CMYK simulations, and state ΔE tolerances; include a disclaimer about device variation.4) What should be in a downloadable dieline?

≥3 mm bleed, 5 mm safety, fold/glue, varnish/foil/white-ink layers, TE markers, barcode & QR zones, and overprint/knockout notes.5) Can I reduce support tickets from prepress issues?

Yes—add a Prepress Checklist (PDF/X, 300 ppi, trapping 0.08–0.12 mm, no overprint on small type) and an automated preflight upload.6) How do I communicate sustainability credibly?

List recycled content %, region-specific recyclability, mono-material options, and disposal instructions via QR—no vague “eco friendly” claims.7) What boosts conversions the fastest?

Sticky RFQ, clear MOQs/lead times, a lucid dieline tab, fast thumbnails, and real-world macro finish photos.