Custom Cigarette Packaging Boxes: Balancing Compliance, Branding, and Luxury

Table of Contents

- Introduction: The Packaging—Tobacco’s Last True Advertiser

- The Core Challenge: Designing Around Regulatory Mandates

- Compliance Checklist: Warnings, Plain Packaging, and Size

- Strategies to Maximize Branding in Limited Space

- Choosing Materials for Protection and Perceived Value

- The Luxury Touch: Advanced Printing and Finishing

- The Importance of Durability (The Pocket Test)

- Sustainability in a Regulated Market

- Frequently Asked Questions (FAQs)

- The Cigarette Packaging Scorecard

- Conclusion: The Art of the Regulatory Compromise

Introduction: The Packaging—Tobacco’s Last True Advertiser

In a world where tobacco advertising is banned across most media (TV, radio, social media), the custom cigarette packaging box remains the final and most visible communication vehicle for the brand. It is a “badge product”—smokers carry and display the pack, making it a constant, mobile advertisement.

For brands, the challenge is immense: they must navigate increasingly stringent global regulations (like Plain Packaging Laws and Buying 3D Products) while still using design to convey premium quality, differentiation, and brand loyalty. The packaging must be technically flawless, highly durable, and legally compliant, which requires expert design precision, yaar.

The Core Challenge: Designing Around Regulatory Mandates

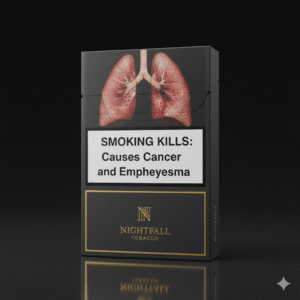

Governments worldwide use packaging laws to discourage smoking, which puts immense pressure on designers. The primary challenge is the shrinking space available for branding due to mandatory Graphic Health Warnings (which can cover 50% or more of the pack).

The Plain Packaging Threat

Countries implementing Plain Packaging (like Australia and the UK) standardize the entire look:

- Uniform Color: Often a drab brown or green (Pantone 448C) that is clinically proven to be minimally attractive.

- Standard Font/Size: Brand names are allowed, but only in a mandated font, size, and color.

- No Branding/Logos: All differentiating elements (colors, logos, texture) are prohibited.

For brands operating globally, custom cigarette packaging boxes must be designed with flexibility to comply with the strictest regulations while retaining an identity for markets that still allow branding.

Compliance Checklist: Warnings, Plain Packaging, and Size

A professional design must accommodate:

- Mandated Warnings: Accurate placement of graphic and text warnings, ensuring they meet the required size and clarity (e.g., covering 50% of the front and back panels).

- Standard Dimensions: The packaging must conform to country-specific standard sizes (like regular, king size, or 100s) for retail display.

- Security Features: Space for technical elements like tax stamps, tracking codes, or QR codes for authentication.

- Tamper Evidence: Secure sealing to guarantee product freshness and consumer safety.

Strategies to Maximize Branding in Limited Space

In markets that still permit some branding, designers leverage premium finishes to signal quality and differentiate the brand:

- Tactile Finishes: Since color and images may be limited, Soft-Touch Coating, Embossing (raised text/logo), and Debossing create a sensory experience that enhances the feel of luxury and keeps the brand memorable.

- Foil Stamping: Using Hot or Cold Foil Stamping for brand identifiers or slim accent lines adds a premium metallic look without requiring large, promotional graphics.

- Color Psychology: Utilizing specific color combinations (Red for strength, Blue for lighter products) to subconsciously communicate the product’s flavor or intensity.

Choosing Materials for Protection and Perceived Value

Cigarettes are delicate; they must be protected from moisture, crushing, and pressure.

- Material: High-quality cardboard or rigid paperboard is essential for maintaining the box’s structural integrity, especially when carried in a pocket (the “Pocket Test”).

- Protection: The box must be precisely sized to hold the sticks in place and often includes inner foil or lining to maintain flavor and freshness.

- Sustainability: Brands are increasingly turning to Recyclable Kraft or FSC-certified cardboard and using soy-based inks to meet growing eco-conscious consumer demand.

The Luxury Touch: Advanced Printing and Finishing

For brands targeting a high-end market or pre-roll specialty items, finishing techniques elevate the perceived value:

| Technique | Purpose in Cigarette Packaging |

| Offset Printing | Best for high-quality, vibrant colors and consistent application across bulk/wholesale runs. |

| Digital Printing | Ideal for short-run orders, limited editions, or test marketing due to fast turnaround and low setup cost. |

| Spot UV Coating | Applying a glossy, raised coating to small areas (like a logo) to create contrast against a matte background. |

Portfolio Showcase: Packaging Design Excellence

See how our strategic designs navigate strict compliance while delivering premium quality and durability for tobacco and specialty products: